- Sectors

- Bakery

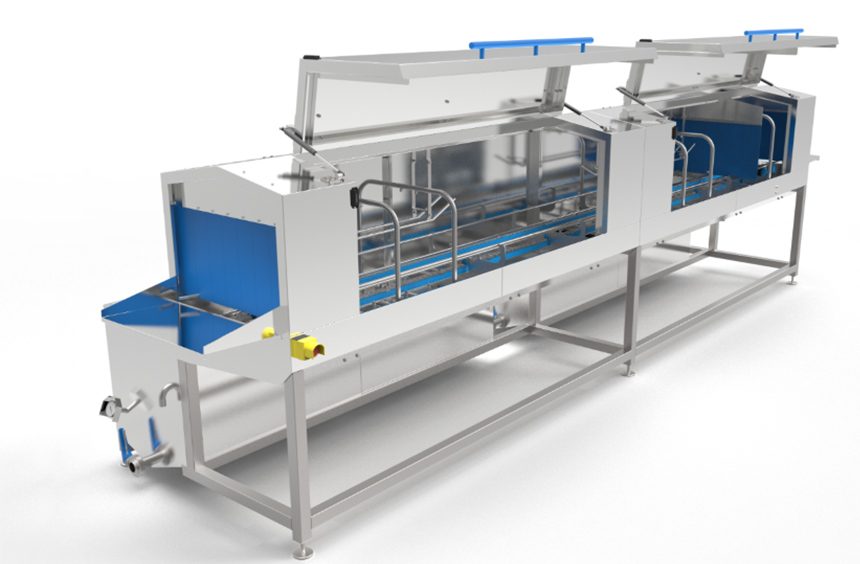

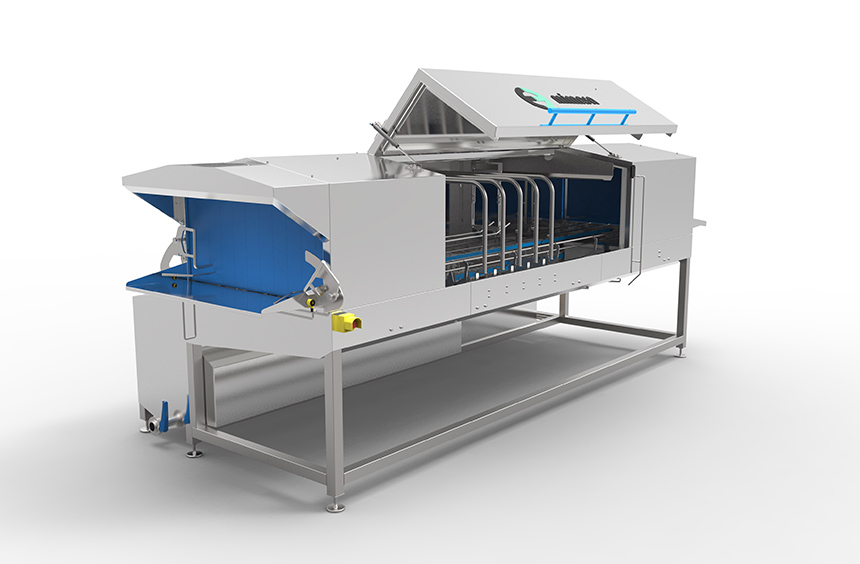

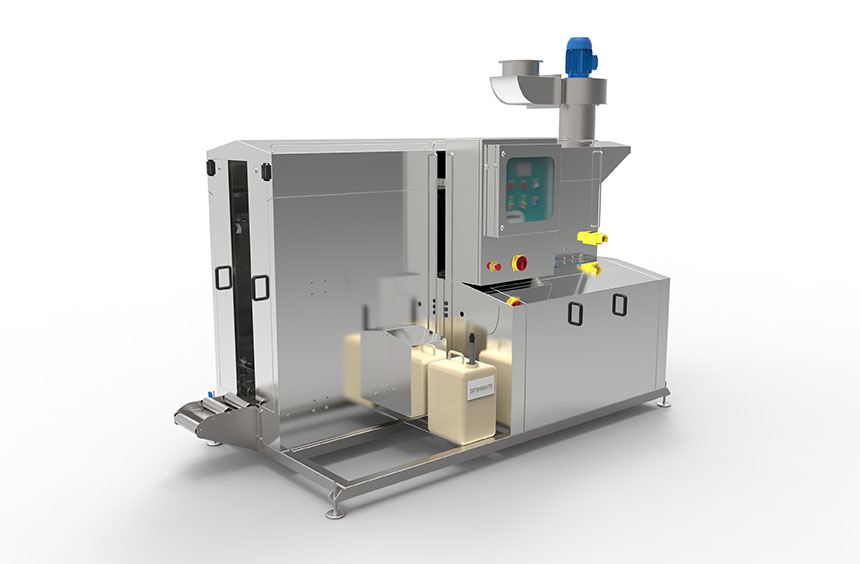

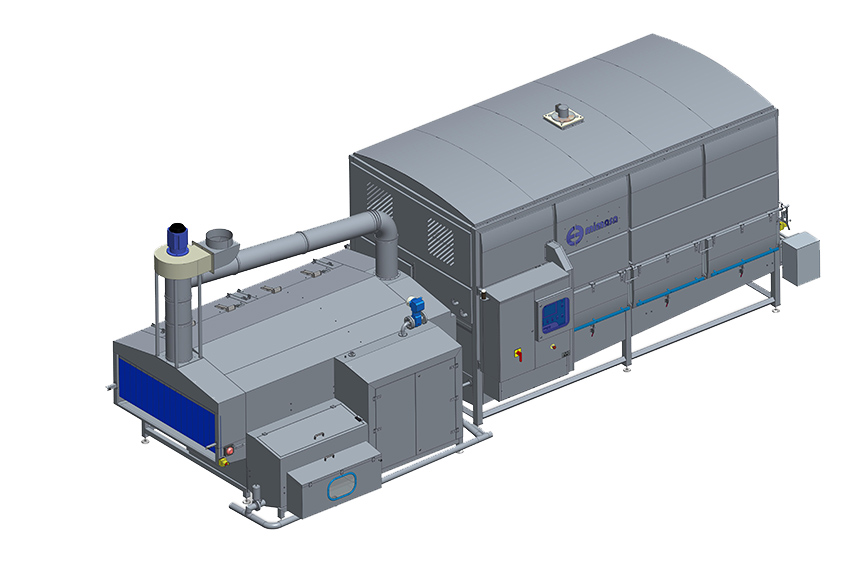

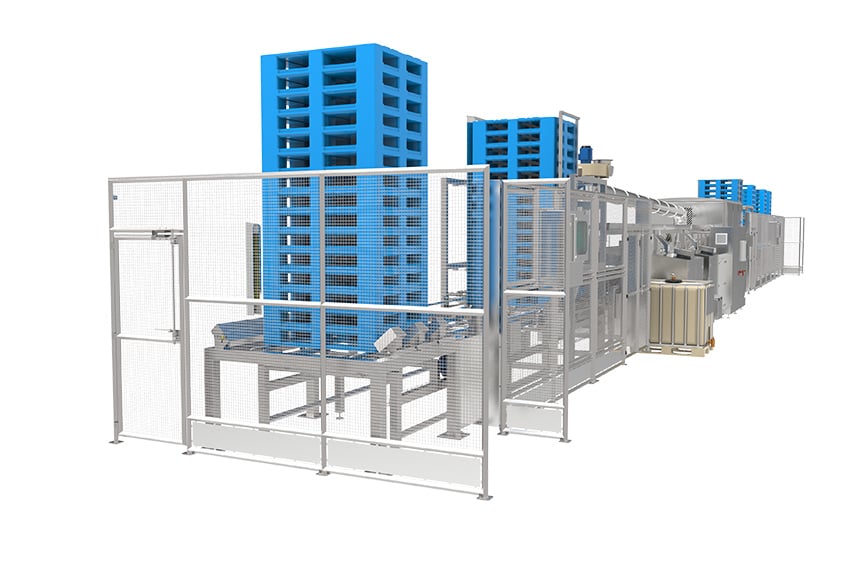

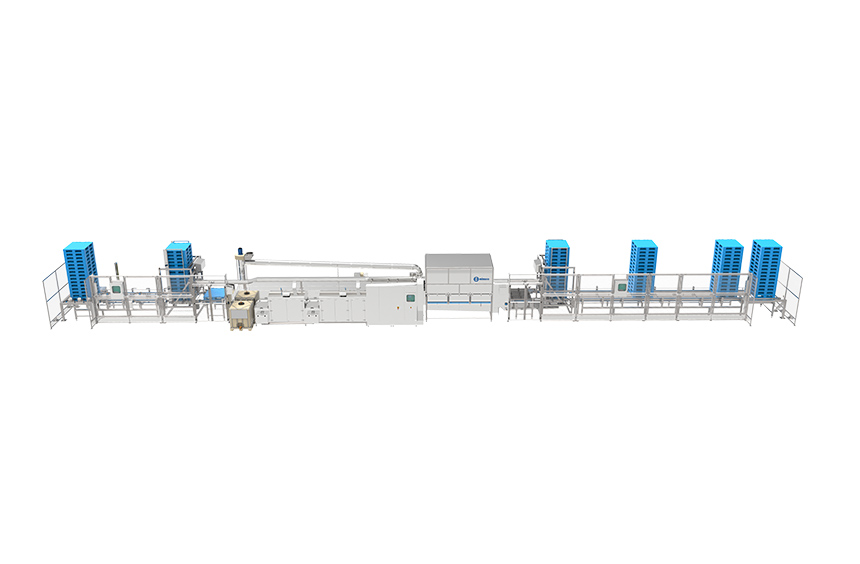

Washing systems

for the bakery sector

The bakery sector has gone through a process of industrialization during the last years, especially bakery bread lines, which work non-stop with a high level of automation. The time used to rinse and to wash all the trays, bins and baking trays, now is shorter, what has become to a very critical point in the production lines.

As in others sectors (f. e. dairy-cheese sector) washing machines are often integrated in the plant production line with an extra phase of the process. It means that once the tray, the bin or the baking tray has passed through all the process and they leave the washing and drying line, they must be ready to be driven automatically at the very beginning of the line to start again the production phase.

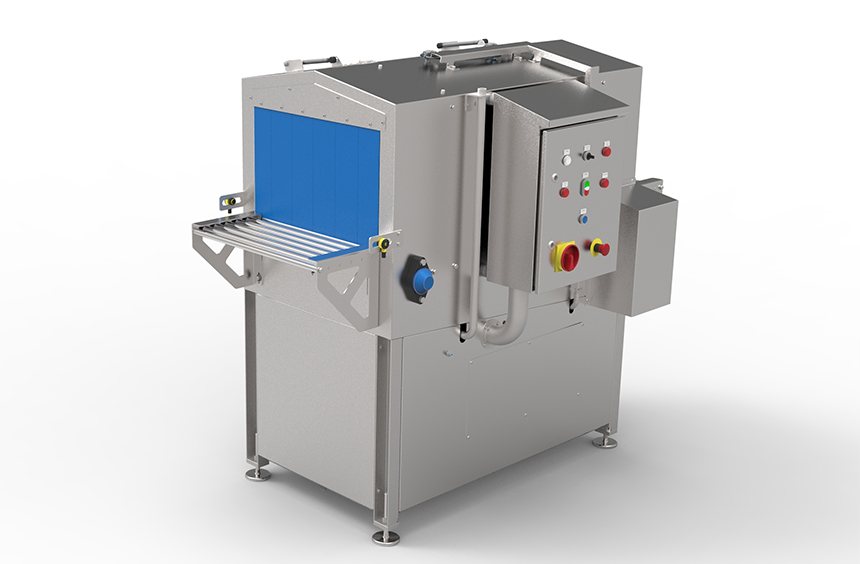

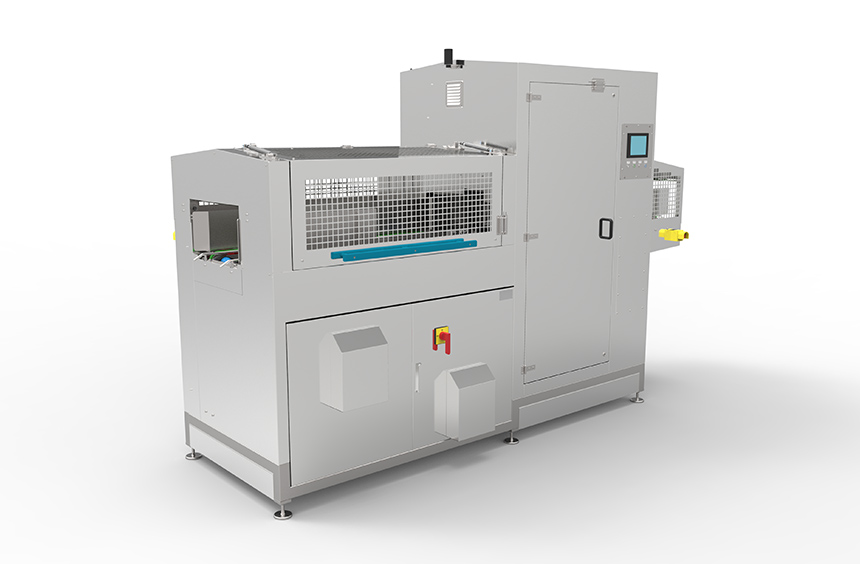

Customized washers for the sector bakery

![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

Learn more![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

Learn more